SAPHEX Industrial Plate Heat Exchangers

About Plate Heat Exchangers

Plate heat exchangers have become one of the most popular types of heat exchanger. There are two popular types the first is the all gasket plate heat exchanger and the second is the brazed plate heat exchanger.

Both types have their advantages, for example the gasket type offer excellent thermal performance to size ratio when compared to a shell & tube heat exchanger design. Upfront cost are cheaper and cleaning and repairs are generally much easier to carry out on the gasket type plate heat exchanger. For these reasons this type of heat exchanger is popular with engineers for many types of industrial applications.

Products Saphex offer.

- Gasketed Units

- Brazed Units Stainless Steel Plates (Copper Brazed)

- Brazed Units Stainless Steel Plates (Stainless Brazed)

- Chemical Flushing (CIP)

- Strip and Clean

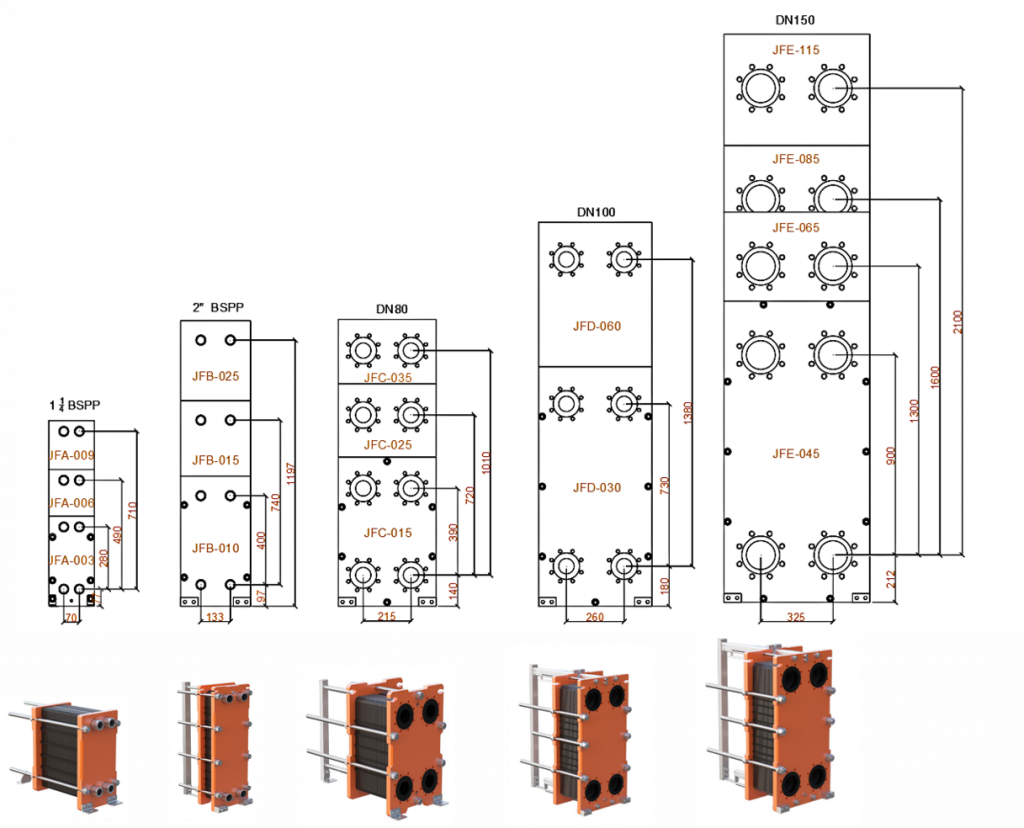

Orange JF Range Gasket Plate Heat Exchangers

- Plate Thickness’s: 0.4, 0.5, 0.6mm

- Plate Material: Stainless Steel 304L/316L, Titanium

- Gasket Material: EPDM, NBR, Viton

- Max Working: Pressure’s 10 & 25Bar

- Max/Min Working Temps : 110Deg C/-10Deg C

.

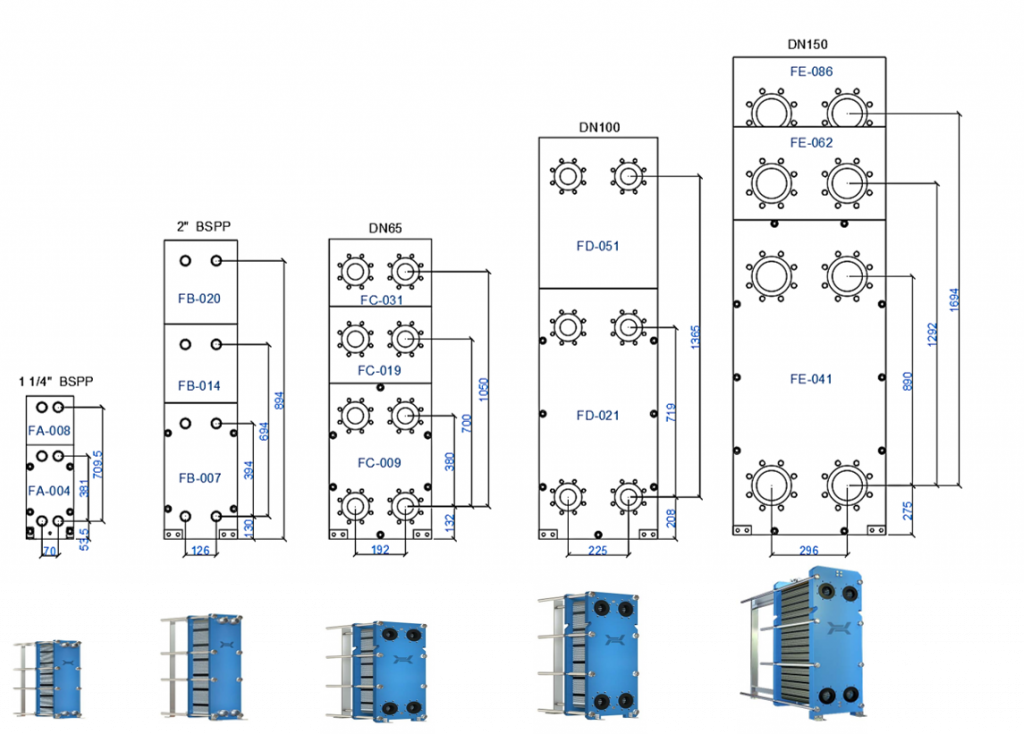

Blue F Range Gasket Plate Heat Exchangers

- Plate Thickness’s: 0.4, 0.5, 0.6mm

- Plate Material: Stainless Steel 304L/316L, Titanium

- Gasket Material: EPDM, NBR, Viton

- Max Working: Pressure’s 10 & 25Bar

- Max/Min Working Temps : 110Deg C/-10Deg C